The main purpose to design municipal solid waste sorting machine is to reduce the amount of the waste and to turn these waste into treasure. The MSW sorting equipment uses a variety of sorting means to maximize the separation rate of organic matter, plastics, metals, masonry and other substances from municipal solid waste, which is to achieve the purpose of improving the garbage recycling rate.

Special Parts of Municipal Solid Waste Sorting Machine for Sale:

1. Programmable controller. The MSW sorting plant is equipped with the programmable controller in the whole operation process. The MSW sorting system has the ability to collect signal from every sensor and conveys them to output control contractor, which is convenient for operators.

2. The rotating screening machine in the MSW plant is patented devices which combine with several sorting approaches. It is invented by the experience of years. Therefore, the failure rate is low, and this machine is particularly suitable for disposing of municipal solid waste.

3. Comprehensive winnowing machine. This solid waste separator adopts the advanced mechanical separation ways. And it can sort the waste into three types. The hole sizes of this machine (large than 50mm and less than 50mm) are adopted to classify two wastes.

4. Bag breaker. The key technology of bag breaker is to organically integrate different breaking and dissociation methods so as to achieve the maximum energy-saving effect in the solid waste plant. In addition, the crushed waste is helpful for the next sorting process.

5. PLC. The PLC control system could monitor the whole working process in the solid waste classification line. In case of any unexpected things occur, we should frequently monitor the PLC.

6. Deodorizing system. The sealed deodorizing system is as the unique spraying deodorant system which contains aromatic ester, and could keep the bad smell in the municipal solid waste plant away. Accordingly, the environment of workshops and the health of workers can be greatly guaranteed.

We’d like to change the solid waste equipment configuration according to customers’ different locations and countries. We are willing to make an environment-friendly and economic garbage plant project for customers coming from different countries.

Applications of Final Products Sorted by MSW Sorting Equipment:

The MSW processing plant has the features of high efficiency, low labor cost and low failure rate. And the sorting rate of above solid waste sorting equipment can reach more than 90%. That’s why municipal solid waste sorting machine is so popular in the domestic and foreign markets. At present, more and more customers from different countries want to buy municipal solid waste sorting equipment. Accordingly, what can we do if we recycle the waste? There are applications of sorted materials for customers’ reference.

1. The waste plastic. Firstly, the waste plastic can be converted to oil by plastic pyrolysis machine. Secondly, the plastic can be recycled to make new plastic products. Thirdly, some materials in the plastic can be used as rubber fortifier.

2. The waste metal. Normally, the waste metal can be packed and directly sold to other industry.

3. The organic matters. We collect the waste organic matters. Then we deliver them into the fermentation system. After a period, we can get the new energy-biogas.

4. Earth and stone. In general, the earth, sand and stone can be made to bricks. We provide available brick maker line for you if you need. The final brick can be used for the construction site. In addition, the charcoal produced by the biochar making machine can also be made to bricks.

By using the above ways, we are able to take full advantage of the waste. With the environmental consciousness improving, we should contribute ourselves to the solid waste separation equipment. In addition, we also get considerable profits from this solid waste separation business.

Specifications of Solid Waste Sorting Plant:

| Model | BFX-100 | BFX-200 | BFX-400 |

| Raw materials | Municipal solid waste, household waste, industrial waste, landfill waste and mining waste | ||

| Capacity | 5T/H | 10T/H | 20T/H |

| Power | 149KW | 224.7KW | 279KW |

| Area | 2400㎡ | 2800㎡ | 3000㎡ |

| Working time | 20 hours | 20 hours | 20 hours |

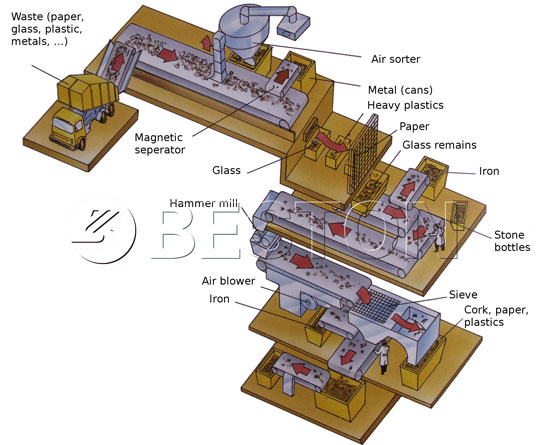

Working Process of Municipal Solid Waste Sorting Equipment:

1. The forklift transports the rubbish to the feeding platform, and the hopper will take away the rubbish.

2. The garbage will be evenly distributed by the feeder, and then be evenly sent to next process by the belt conveyor.

3. Workers will pick out the large waste (large branches, sticks, bricks, bottle, etc.) when the garbage goes through the manual sorting platform.

4. The rubbish will be separated by rotating screening machine, and will be sorted into two kinds of rubbishes. The first one is that the diameter is large than 50mm (the plug hole size is designed carefully according to the reality of garbage). These materials are mainly classified into the bottle, plastic, shoe sole, and so on. The second one is less than 50mm undersized material which is metal. At the same time, the waste metal will be picked out by strong magnetic separation machine.

5. The plastic will be packed by packing machine; the heavy material will be directly sent to outside for landfill or be crushed to make bricks; we can pick out the useful material from the mixture material, then recycle them.

The whole MSW sorting system takes advantage of several advanced sorting methods, and just need few people to operate. At the same time, the sorting rate is so high and don’t need workers to operate all the time in the municipal waste recycling plant.

After-sale Services We Beston Machinery Offer:

1. Customized service. Based on our customers’ site and budget, our experts will design appropriate solid waste sorting plant drawings for you.

2. Installation service. We will dispatch experienced engineers to install and debug the MSW sorting machines in your site according to your demand. Besides, it is also available for our engineers to provide training for your faculty.

3. Periodical call visit. We want to make sure that there are no problems with the household waste sorting machine. Besides, we also hope to establish a long-term friendly cooperative relationship with customers.

4. Providing visiting service. If you want to know more detailed information about municipal waste sorting machine and determine to visit Beston Machinery’s municipal solid waste sorting machine manufacturing plant, we welcome you at any time. Our personnel will pick you up at the airport or at the station.

The solid waste management machines have different models, including BFX-100, BFX-200, BFX-400. and their capacity ranges from 100 to 400T per day, which satisfies the different requirement of customers. Do you want to know more information about Beston municipal solid waste sorting machine? Why don’t contact us directly? We have professional personnel to deal with your question. Email us right now.