With the increasing population of cities, the trash sorting machine has become popular in many countries, like Hungary. Recently, the urban waste shows an increasing trend. In the face of a lot of the waste-trash generated by human, then how do we quickly achieve the classification of the trash? The answer is full automatic trash sorter machine. This kind of recycling equipment can make the work of sorting trash become easier. At the same time, this machine will save large labor cost.

The trash sorter machine is designed based on principle of the reducing the trash volume and turning the waste to treasure. By using a variety of trash separation systems with high efficiency, we could get organic, plastic, metal, brick, stone, etc. from the garbage. The sorting rate of the above rubbish can reach more than 85%, and the sorting rate of film plastic reaches more than 90%.

Do You Know the Characteristics of Trash Sorting Machine for Sale?

1. The rotary screen machine. The rotary screen machine is mainly used to select the large material which is larger than 50mm and the small material which is smaller than 50mm. This process effectively classifies the waste to two types. Besides, according to the different demands of customers, we also can add blade in the inside of the rotary screen machine which can achieve the breaking effect.

2. The smooth automated feeder. This kind of feeder can deliver the trash to the next trash sorting process automatically which saves manpower. In addition, this machine can make the trash distribute evenly on the belt, which makes the next step more smooth.

3. The PLC system. The PLC control system is able to monitor the whole working process of solid waste management system. Once any unpredictable things occur, we can adjust in time. Therefore, this machine greatly guarantees the security of the trash sorting facility.

4. Comprehensive winnowing machine. The comprehensive winnowing machine adopts several rubbish classification principle, such as specific gravity method, volume method, cyclone separation method, etc. The waste can be mainly classified to three types, including film plastic, mixture material (hard plastic, rubber products, wed paper, textiles, etc) and the heavy material (bricks, stone, rubber overshoes, glass, etc). After processed by this trash separator, the sorting rate is greatly improved.

What Materials Can be Sorted from the Trash? And What Can These Sorted Material Do?

As is know to all, the trash is composed of different waste, such as plastic, branch, chicken waste, etc. And in different countries, there is a big gap in the components of the waste. We would like to know your detailed information, and will design an appropriate solid waste recycling plant for you.

1. The waste plastic. There are three methods to recycle the waste plastic. The first one is using waste plastic pyrolysis machine, which can turn the plastic to oil. Secondly, some material in the plastic can be used as the rubber fortifier. Thirdly, we can sell the waste plastic to other industry to make new plastic product.

2. The stone, sand and waste construction material. Do you think these waste is useless? However, we can use these waste to make bricks by brick maker line. Nowadays, the technology, making brick with the earth, stone, sand or the carbon black from the pyrolysis trash, is complete and mature.

3. The organic matters. After picking out some unavailable material, we can send the organic matters to fermentation system, then this system will generate biogas as energy.

4. The waste metal. After packed by packing machine, the waste metal can be directly sold to other industry to make new metal product.

Safety Design of Beston Trash Sorting Machine:

Every plant always puts the safety of workers in the first place. So do we. Beston trash recycling machine adopts several parts to strengthen the security of plants.

1. Fully sealed working model. In daily life, the trash always has bad smell and some bacterial which is harmful to our health. Therefore, Beston Machinery has designed a fully sealed automated sorting system to protect the health of workers and the environment of workshops.

2. Unique odor control system. This deodorizing system, as the unique aromatic ester spraying deodorant system, could keep the bad smell in the workshop away. This system has the flowing advantages:

a. Excellent deodorizing effect.

b. Low energy consumption.

c. Convenient maintenance method.

d. Continuous working method and stable operation.

3. Sound control method. All engines Beston msw processing plant adopts have dust-proof and noise-proof cover. This cover has effective effect, and the noise of the sorting equipment is small than 80db.

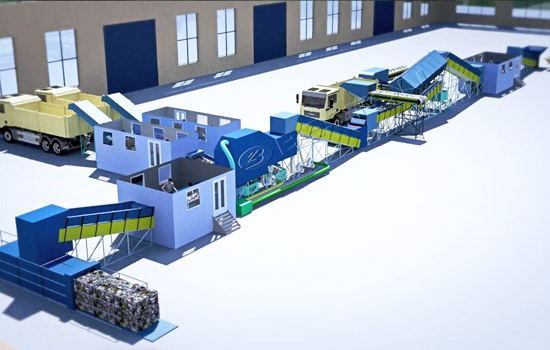

Smooth Working Process of Trash Recycling Equipment:

1. The forklift transports the rubbish into the rubbish bin, and the hopper floor conveyor will take away these rubbish.

2. The garbage will be balanced by evenly distributing feeder, and then be sent to next process after the first belt conveyor.

3. Workers will pick out bulky waste when the garbage goes through the manual sorting platform. The large stuff will be picked out by labor, such as old quilt, branch, long sticky, large piece of construction material, etc in the solid waste sorting plant.

4. These rubbish will be separated again by rotary screen machine, and will be sorted into two kinds of rubbishes, the diameter of sorted material is large than 50mm or less than 50mm.

5. Then the undersized material is as raw materials for the system of the fermentation. The diameter more than 50mm sieve material will be delivered to other devices (such as magnetic separator, comprehensive winnowing machine).

6. At finally, we can get four types of the waste. After picked by human, these waste can be dealt with different methods, including recycling, packing, burning, landfill, fermentation, etc.

Beston Trash Sorting Machine Technical Parameters:

| Model | BFX-100 | BFX-200 | BFX-400 |

| Raw materials | Municipal solid waste, household waste, industrial waste, landfill waste and mining waste | ||

| Capacity | 5T/H | 10T/H | 20T/H |

| Power | 149KW | 224.7KW | 279KW |

| Area | 2400㎡ | 2800㎡ | 3000㎡ |

| Working time | 20 hours | 20 hours | 20 hours |

Three Advantages of Beston Machinery:

1. Providing superior rubbish sorting machine. The garbage separation machine is carefully designed by Beston engineers. Accordingly, it satisfies with the demands of customers, such as high efficiency, favorable cost, energy saving, environmental protection, etc.

2. Professional group team. Beston Machinery, as the professional trash processing plant manufacturer in China, has decades of experience. Our experienced engineers possess the capacity of designing appropriate waste sorting plant and technical support for customers.

3. A comprehensive range of services. The customers who choose Beston Machinery not only think we provide high-quality trash sorter but also trust our customer-oriented service, such as installation service, customized serve, training service, turnkey project, etc.

If Beston trash sorting machine for sale is the machine you want, email us right now to get the information you need!